48-hour fast delivery

Abundant raw materials, fully in-house manufacturing process

Launch your project immediately

Quick response, fast delivery

HSX has been developing in the PCB manufacturing field for 30 years. The company has two highly automated production bases and a team of over 300 engineers and employees. At HSX, we can complete more than 6,000 projects every month, with both delivery time and yield rate exceeding 99%. Once HSX receives your production files, we can complete full-scale DFM optimization within 1 hour, launch the NPI management system to start production, and finish factory testing and delivery in as fast as 48 hours.

1-hour DFM optimization

48-hour production and delivery

99% yield rate, delivery time

Abundant raw materials

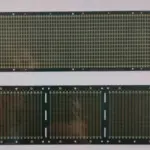

HSX is particularly skilled in the rapid delivery of high-precision, complex printed circuit boards. Our raw materials warehouse stocks a variety of mainstream HDI manufacturing substrates. Once the DFM optimization is confirmed by you, we can quickly start material preparation and enter the production process. This is a key factor that enables HSX to respond and deliver quickly. Even when special material requirements arise, thanks to our well-established supply chain system and regular inventory, HSX can flexibly meet diverse customer needs, seamlessly connecting small-batch rapid prototyping with stable mass production.

High Tg FR-4

High-Speed High-Frequency

Low Dk/Df Resin Systems

Metal Core & Hybrid

Polyimide

Halogen-Free

Full-process internal machining

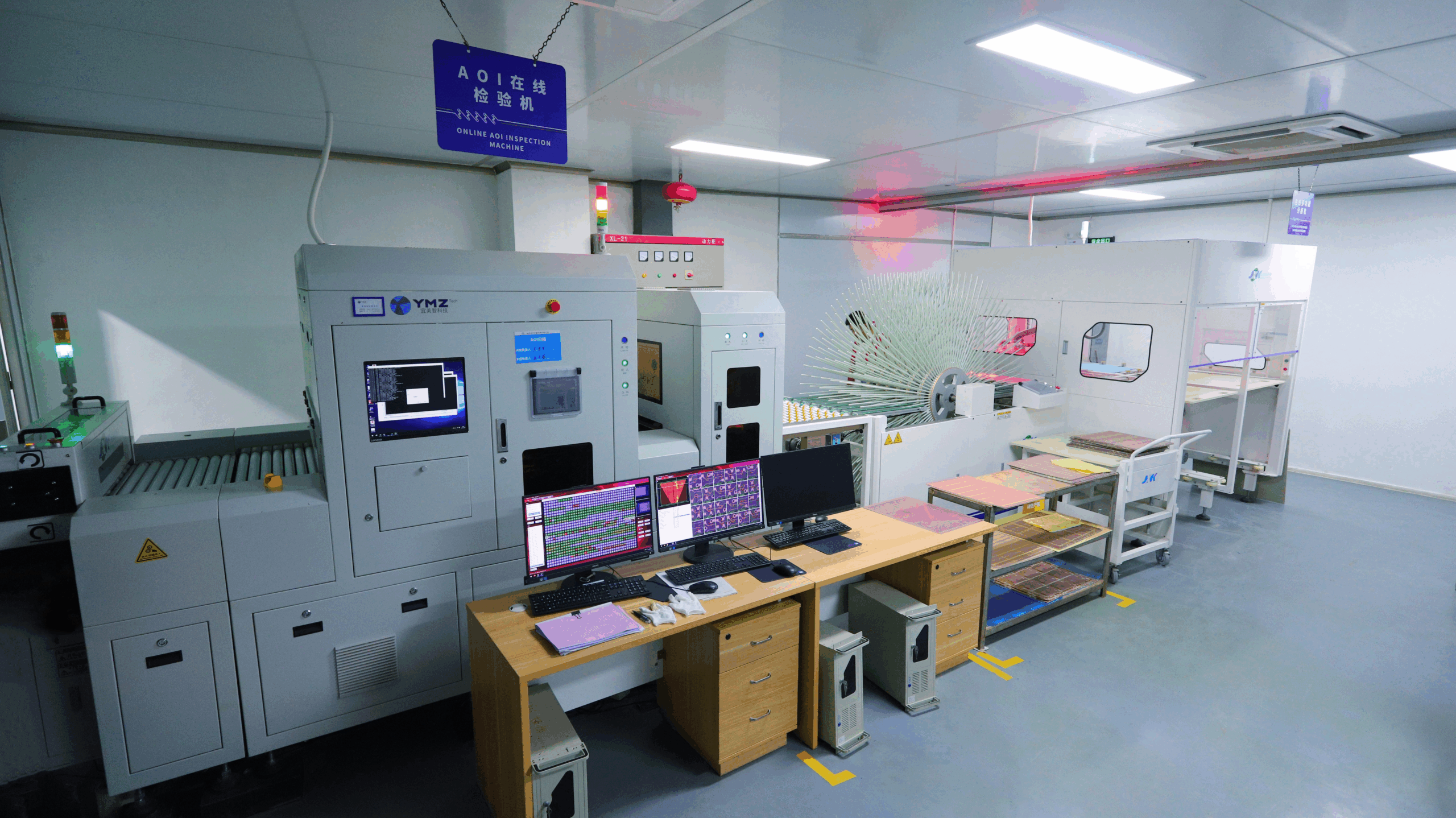

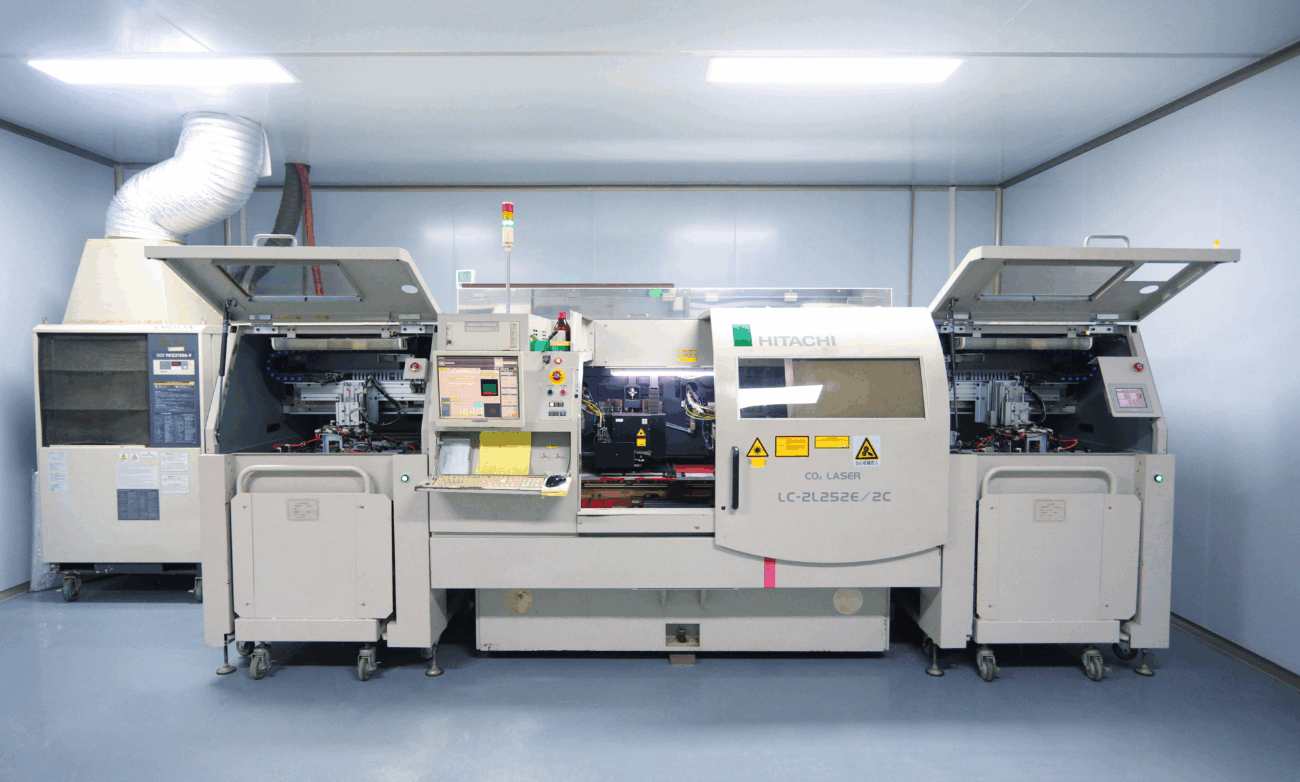

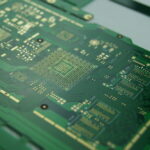

We combine leading technology with excellent manufacturing capabilities, dedicated to providing high-quality PCB products. Both of the company's production facilities have full-process production lines. Over the past 30 years, our key equipment has been continuously updated, and AI technology has been introduced in line with technological advancements, keeping our production lines at the forefront of automation and intelligence. The combination of advanced equipment and precise processes allows HSX to consistently meet end-to-end requirements for various PCB products, ensuring delivery quality and reliability.

Key Equipment for HDI PCB Manufacturing

Laser drilling machine

Copper-clad wire

Pulse plating line

Laser Imaging Device (LDI)

Vacuum lamination line

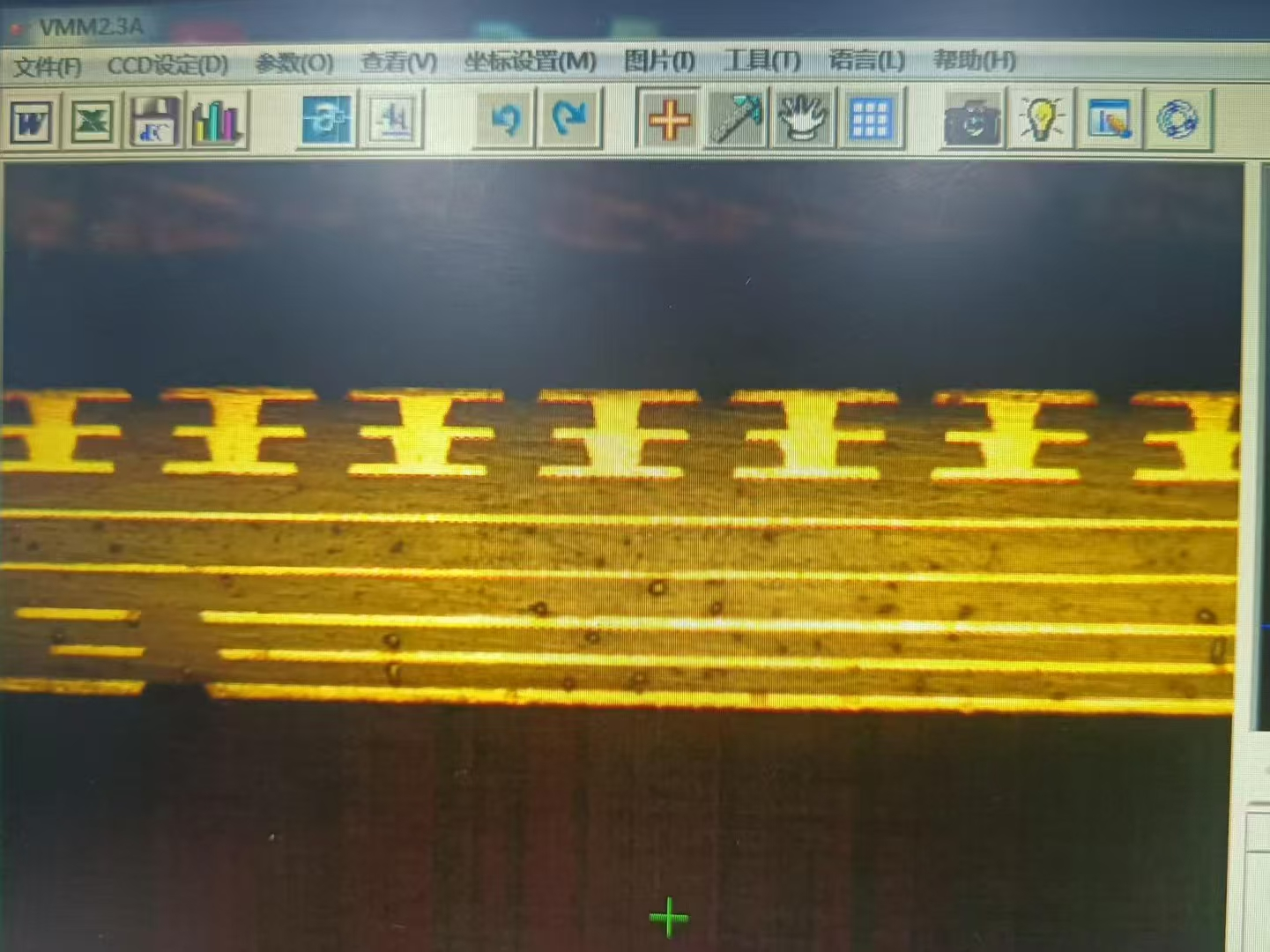

Fine etched lines

Systematic quality control

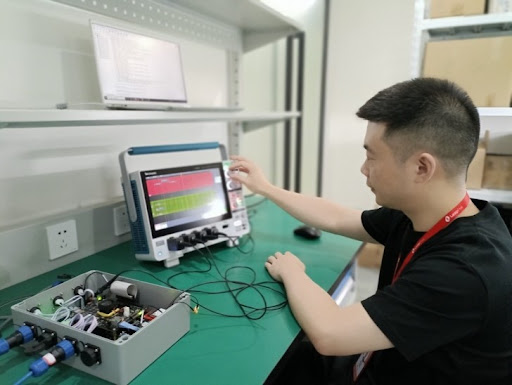

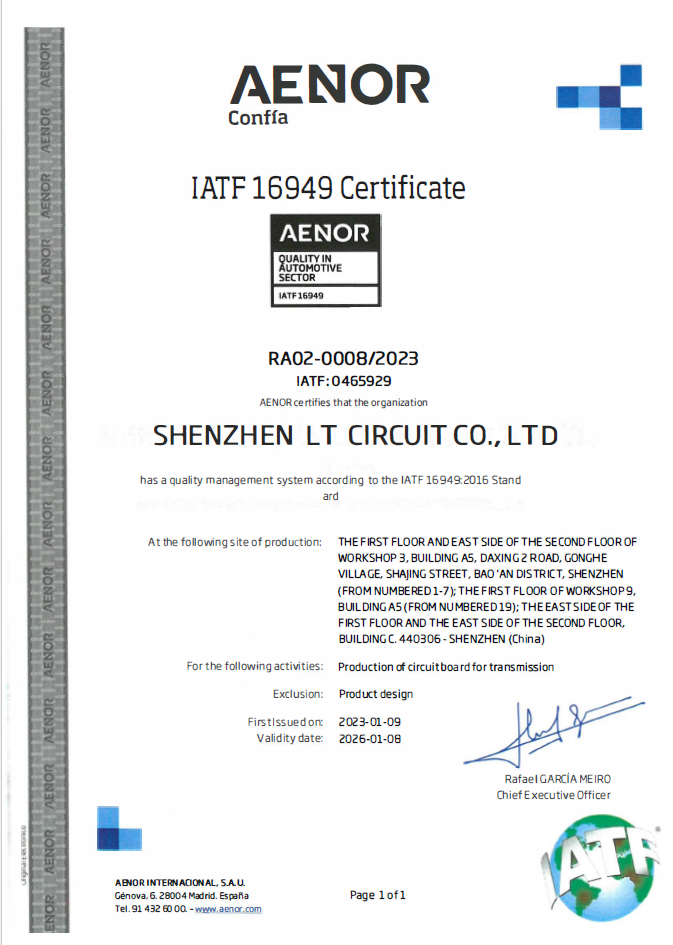

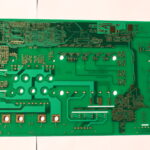

At HSX, we have established a comprehensive full-process quality control system to ensure that every PCB product meets the highest standards. For each project, we promptly conduct strict reviews of the design documents to ensure compliance with Design for Manufacturability (DFM) and process requirements. Throughout the PCB manufacturing process, multiple professional inspections are carried out, including AOI (Automated Optical Inspection), X-ray inspection, pad and hole size control, with real-time monitoring of each critical procedure. Before delivery, every project undergoes Flying Probe Testing, impedance testing, electrical performance testing, and reliability verification to ensure stable and reliable product performance. HSX holds ISO9001, UL, IPC, and medical device-related certifications such as ISO13485, ensuring products meet global and medical industry standards.

What kind of projects can HSX handle?

HDI PCBs account for more than 60% of HSX's production capacity. With a fully in-house production system, we have accumulated extensive experience in special processes such as any-order connections and laser blind via embedding. Every month, our factory ships over 6,000 types of components, covering a wide range of fields including communications, automotive, IoT, and medical sectors. Our professional engineering team possesses strong technical and processing capabilities. From complex designs to urgent orders, we can efficiently execute the production process. With large-scale production capacity and superb technical skills, we are able to meet the diverse needs of customers worldwide.

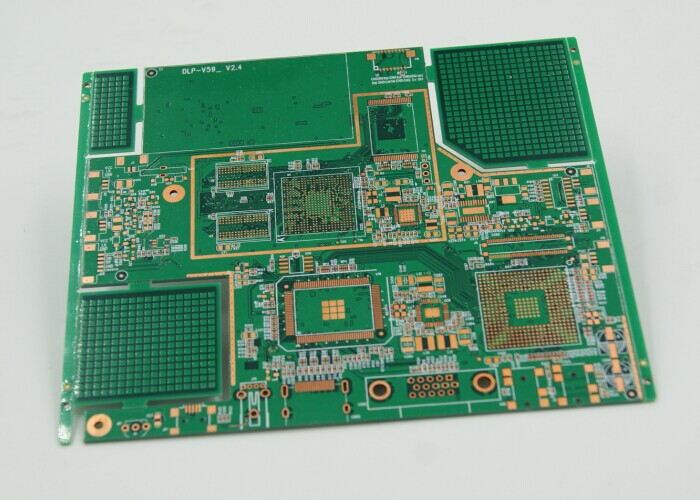

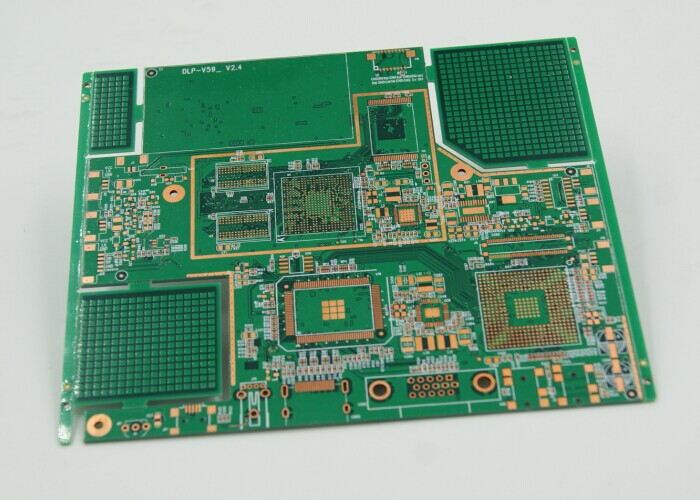

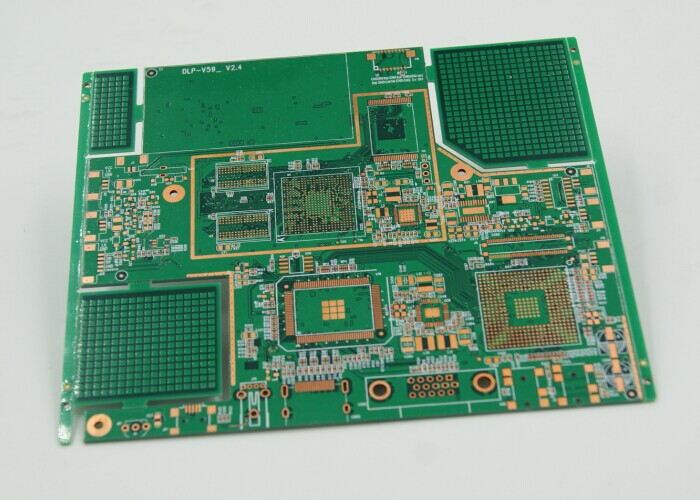

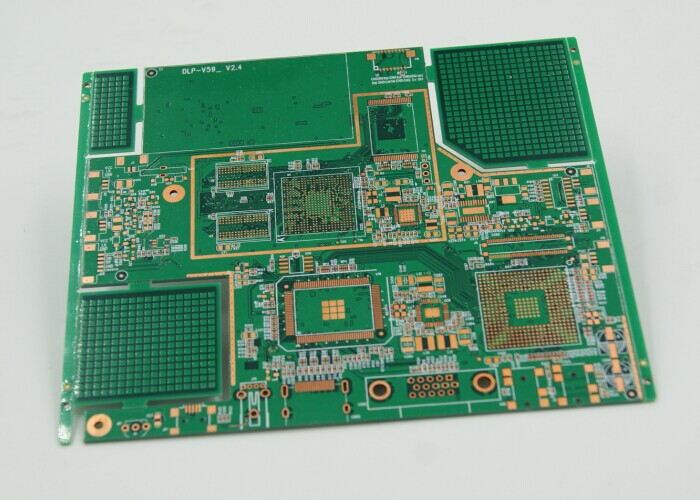

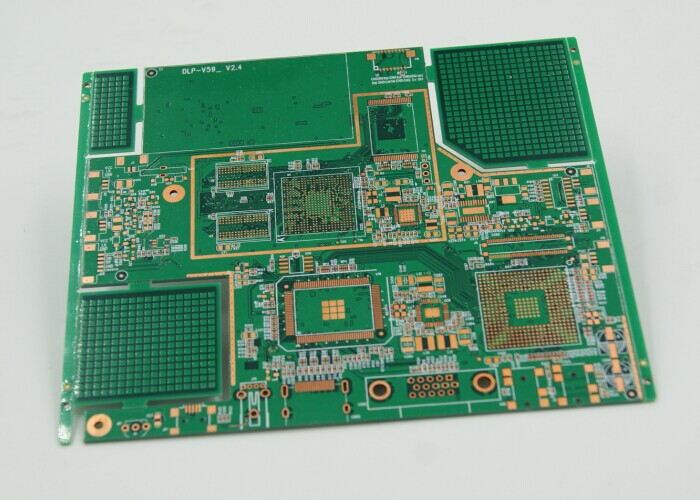

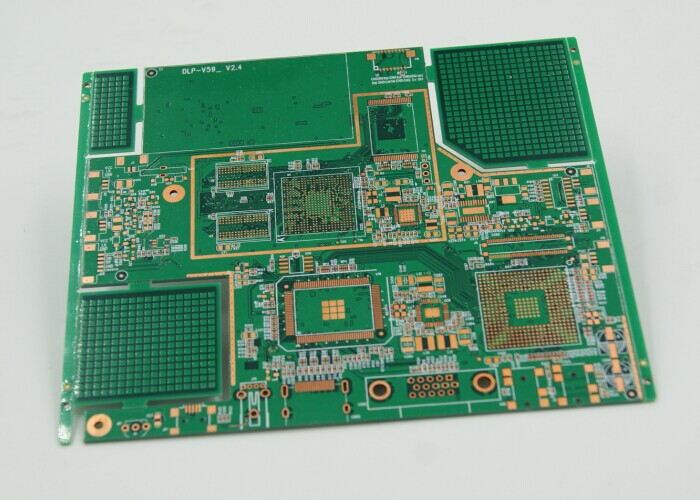

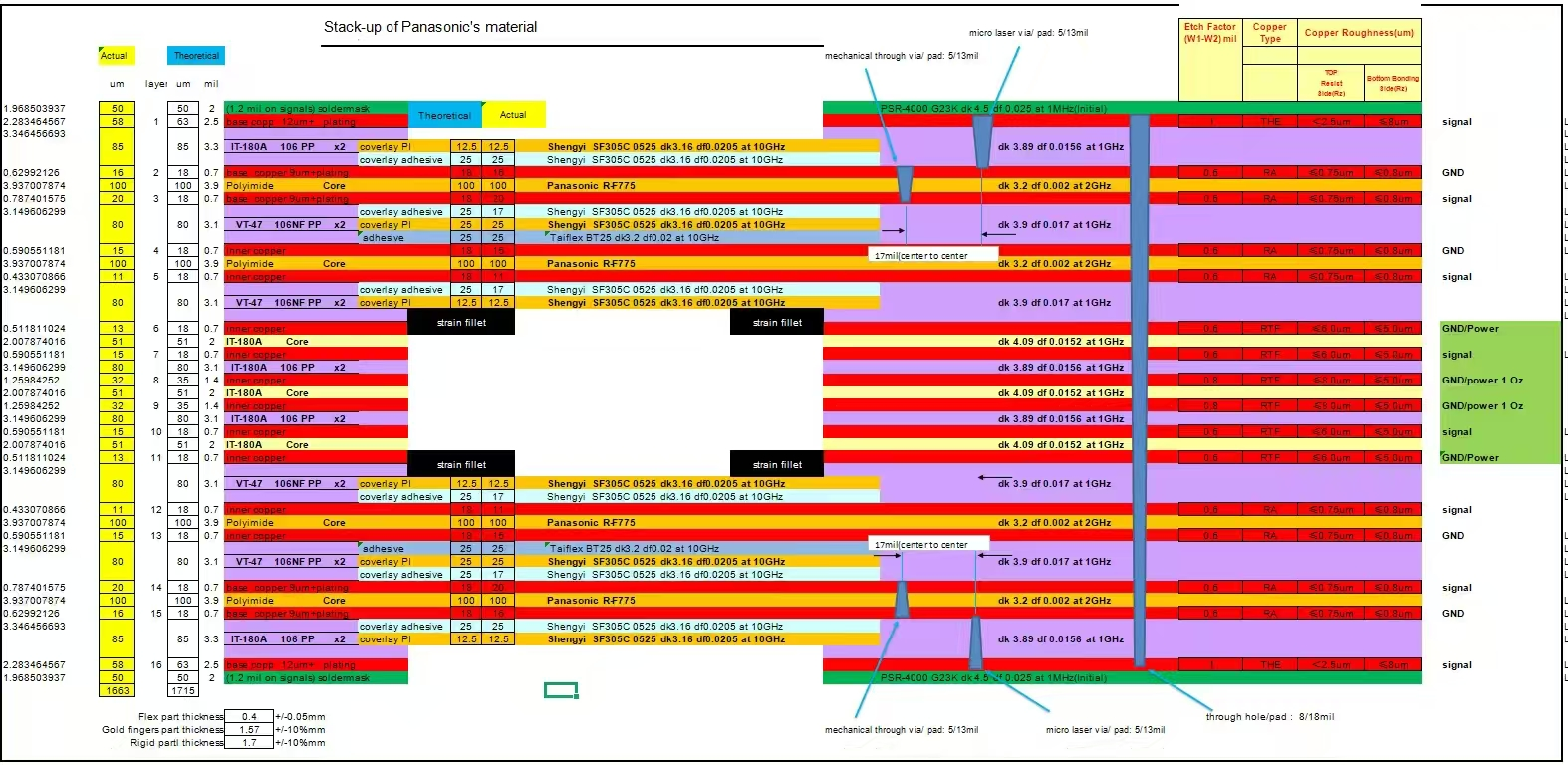

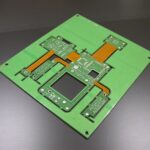

Our Case 1:

This product is a 16-layer high-frequency HDI product that integrates both software and hardware. Its special structure is relatively complex. The multilayer stack-up includes signal layers, ground layers (GND), and power layers (GND/power). The large number of layers increases the difficulty of processes such as interlayer alignment and lamination, and also makes it difficult to control material properties. Various materials with different characteristics are used, such as Panasonic RF775 and Shengyi SF305C. Each material has distinct parameters, including dielectric constant (dk) and dissipation factor (df). In high-frequency environments, material properties must be precisely controlled to meet electrical performance requirements. The difference in thermal expansion coefficients between materials can also easily lead to issues like warpage. Via processes have extremely high requirements. There are mechanical vias and micro laser vias. The production of micro laser vias requires high-precision processes such as laser drilling, and has extremely strict demands on equipment and process control. Additionally, the aperture of mechanical via pads and the quality of hole walls can also affect the reliability of electrical connections.

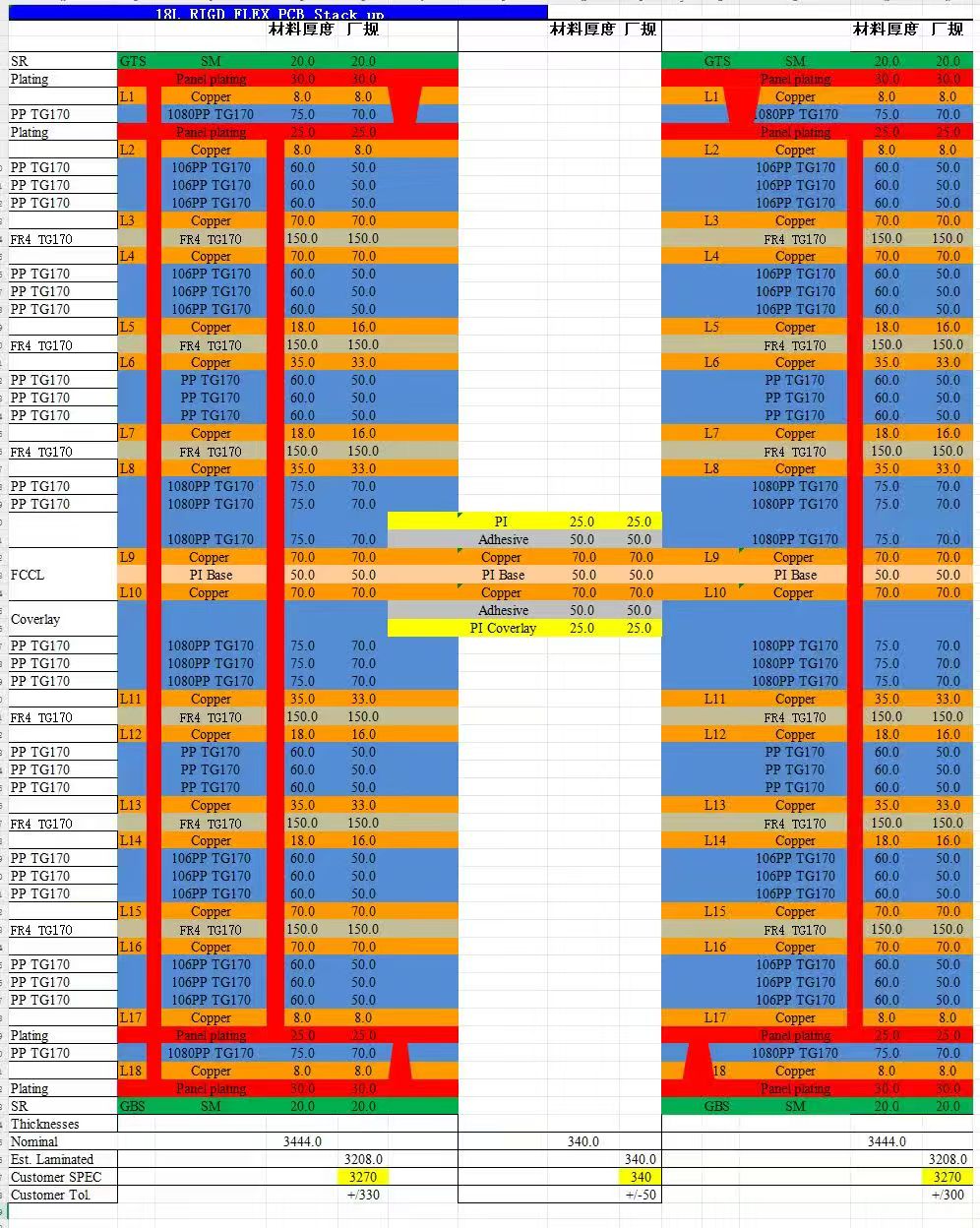

Our Case 2:

Our solution

Ceramic PCB Board

Double Sided PCB

HDI Any Layer PCB

HDI PCB Board

Heavy Copper PCB

IC Substrate PCBs

Multilayer PCB Board

Rigid Flex PCB

Rogers PCB Board

Substrate Like PCBs

|

Item |

Process Parameter |

||||||

|---|---|---|---|---|---|---|---|

|

Layer Count |

Prototype |

2-64L |

Mass Production |

2-48L |

|||

|

Board Thickness |

Prototype |

0.15-10mm |

Mass Production |

0.15-8.0mm |

|||

|

Min. Trace Width/Space |

Prototype |

2.5/2.5mil |

Mass Production |

3/3mil |

|||

|

Max. Aspect Ratio |

Prototype |

16:01:00 |

Mass Production |

12:01:00 |

|||

|

Min. Hole Size |

Laser Drill |

0.1mm |

Mechanical Drill |

0.15mm |

|||

|

Impedance Control |

±10% |

||||||

|

Max. Production Size |

620mm x 1300mm |

||||||

|

Copper Thickness |

0.5oz-20oz |

||||||

|

Min. Hole to Trace Space |

PTH |

0.15mm |

|||||

|

NPTH |

0.125mm |

||||||

|

Finished Hole Size Control |

PTH |

±0.075mm |

|||||

|

NPTH |

±0.03mm |

||||||

|

Solder Mask Color |

Green, Blue, Black, Yellow, Red, White, etc. |

||||||

|

HDI (Blind/Buried Hole) Board |

1+n+1,2+n+2,3+n+3,4+n+4,5+n+5,ELIC |

||||||

|

Base Material |

SYTECH, ITEQ, KB, ROGERS, EMC, TUC, Panasonic M6, ISOLA 370HR, Hybrid Press Materials,etc. |

||||||

|

Surface Finish |

OSP, ENIG, ENEPIG, Immersion Tin, Gold Plating, Lead-free HASL, HASL, Immersion Silver,etc. |

||||||

|

SMT Pitch |

0.3mm |

||||||

|

BGA Pitch |

0.2mm |

||||||

|

Board Warpage Control |

±0.5% |

||||||

|

Min. Outline Tolerance |

±0.05mm |

||||||

|

Special Processing |

High Frequency, High Speed, HDI, Blind/Buried Holes, Rigid-Flex, Any-Layer Interconnection, FR4-Rogers Hybrid, Step Slot, Back Drilling,etc. |

||||||